Unlock the Hidden Story of Your Wind Turbine with DL1300 Dataloggers

Wind Turbines are complex systems, powered by a symphony of sensors, input cards, and intricate cabling. These components communicate with the Wind Turbine’s Controller, making critical decisions to optimize performance. But what if we told you that there’s a missing piece in this puzzle?

The Problem: Hidden Insights

While the Controller stores valuable data internally, it remains inaccessible to external users. This limitation poses a challenge for understanding the historical behavior of Wind Turbines—a crucial aspect for Due Diligence reports.

The Solution: DL1300 Dataloggers

Our cutting-edge DL1300 dataloggers bridge this gap. Here’s how they revolutionize Wind Turbine monitoring:

- Comprehensive Signal Logging:

- DL1300 captures every signal arriving at the Controller (inputs) and monitors its output signals (which control subsystems within the Turbine).

- No more missing data—our dataloggers ensure a complete record of your Turbine’s performance.

- Tailored Installation:

- Each DL1300 project is customized for your specific installation.

- We consider sensor connections, additional cabling, and electronics placement, respecting existing cabinets and ensuring uninterrupted plant operation.

- Data Accessibility:

- Say goodbye to resource-intensive queries to the Controller.

- DL1300 provides direct access to detailed historical data without disrupting the Turbine’s operation.

Why Choose DL1300?

- Reliable Insights: Understand your Wind Turbine’s behavior like never before.

- Streamlined Workflow: Simplify your monitoring process with user-friendly interfaces.

- Exportable Data: Extract valuable information without affecting the Controller’s performance.

Don’t let hidden histories hold you back. Invest in DL1300 dataloggers and unleash the true potential of your Wind Turbine!

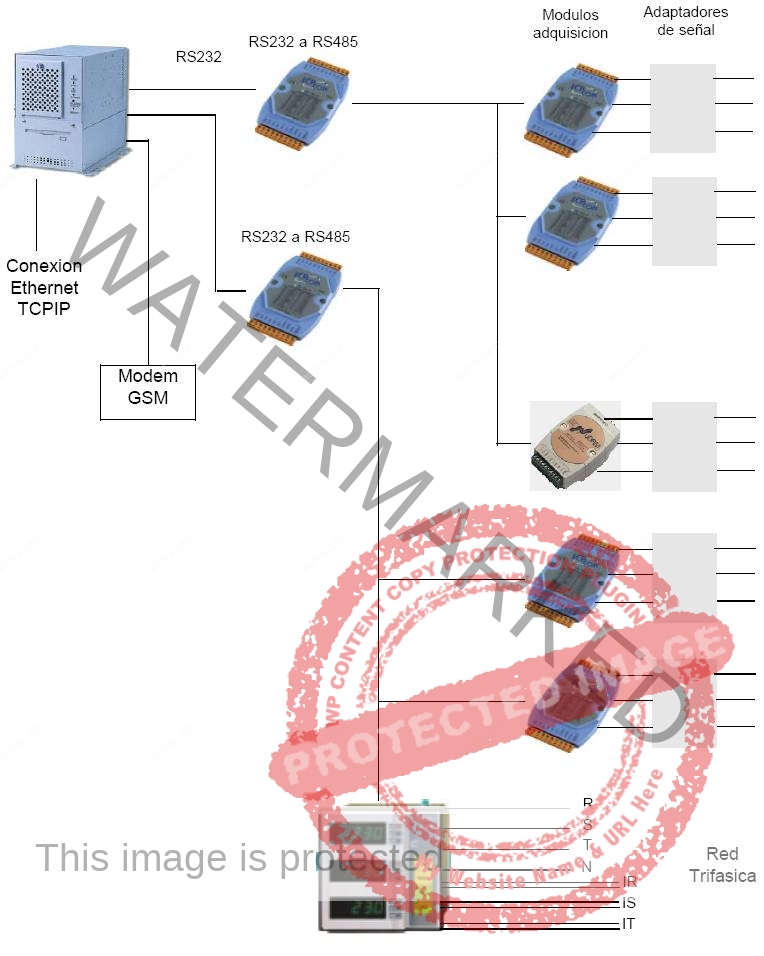

Typical structure

- The types and number of sensors.

- The type of connection between the sensors and the Controller. analog (4-20 mA, 0 to +5V, -10V to +10V), frequency, specific protocol (RS485, RS232, CANBUS, etc.)

- Availability of space for the additional Electronics inside the cabinets

- Accesibility to the central computer.

A typical layout with remote Electronics cards near the sensor, with the additional Electronics for the sensor interface, and communications through serial lines (copper, or fiber optic) is shown in the next figure.

Main advantages and characteristics

-

Effortless Deployment:

Thanks to our streamlined engineering, these dataloggers can be easily installed by Wind Turbine maintenance technicians.

No Programming Required:

Simply use a configuration file to specify all the essential details:

- Connections

- Communication lines

- Mapping physical channels to signal names (tags)

- Sampling period settings

Signal-Specific Treatment:

Our dataloggers address specific requirements for each signal (tag):

- Minimize resulting file size.

- Collect sufficient samples for analog signals.

- Capture all changes in digital signals.

- Precise timestamps with better than 1-millisecond resolution, including full date descriptions.

Robust Connection Tolerance:

The logger detects communication line disruptions or non-functioning input devices. No data is stored until the line or device becomes operational again.

Data Loss Protection:

Instead of storing all logged data in a single database file, we split them into several files online. This way, only some of these files may be affected in case of storage malfunctions.

Application to remote Control of the Datalogger

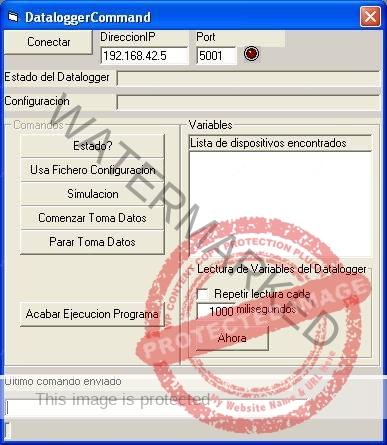

The datalogger works as a standalone application in a real-time Linux computer. The bootstrapping of this Linux machine executes all the programs required by the DL1300 applications and the own application. In this way, turning on the Linux machine starts the data logging process.

One of the threads of the DL1300 ‘listens’ the commands issued to a particular IP address. The DL1300 is supplied with a Windows application that uses TCP/IP communications to know about and control the DL1300 application running in the Linux machine. See the next figure.

Logged data files can be transferred using standard FTP protocol.

Data visualization and analysis

The DL1300 uses compressed XML files to store the collected data. It comes with an application that allows:

- Transformation of the internal data to any SLQ based data base manager. By default, MS Access / MS SQL SERVER

- Visualization of the recorded data using the ‘Oscilloscope‘ application.

- Tools to edit the raw data (to eliminate noise, missing data, etc.)